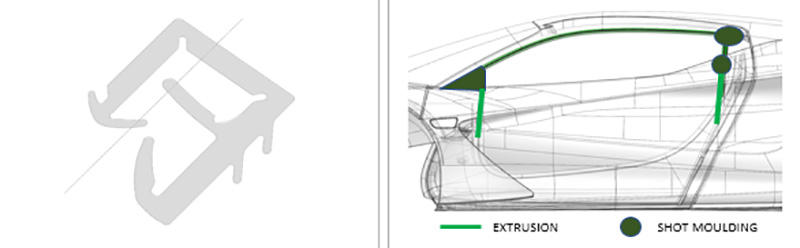

Seal mold and products

1: Used in automobiles.

Shot moulding and extrusion parts for automotive sealing. EPDM60 SHORE A.

2: Technical analysis.

When we receive the customer’s drawings, we will conduct a full manufacturability analysis of the drawings and maintain communication with the customer until the customer is satisfied

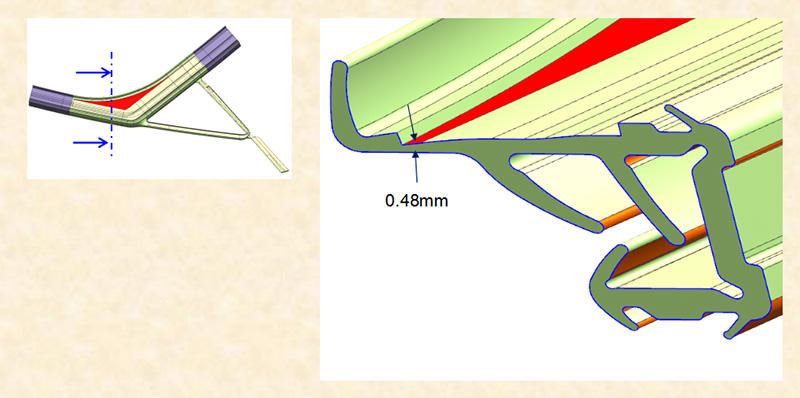

Thin wall thickness, There are some areas with thin wall thickness, They will be easy to break during production and use, so we suggested customer increase it to 1mm at least. then solved this problem.

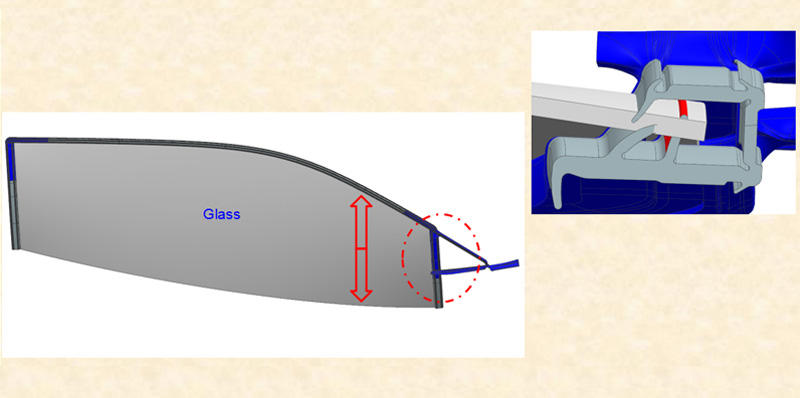

Rib inside, we found inside rib too high, and impossible to demolding, we asked customer provide assembly drawing of glass wiith seals, then found a question as show the picture, That the seal intervened with glass, so we suggestend cutomer reduce the height of the rib, then solved all the questions.

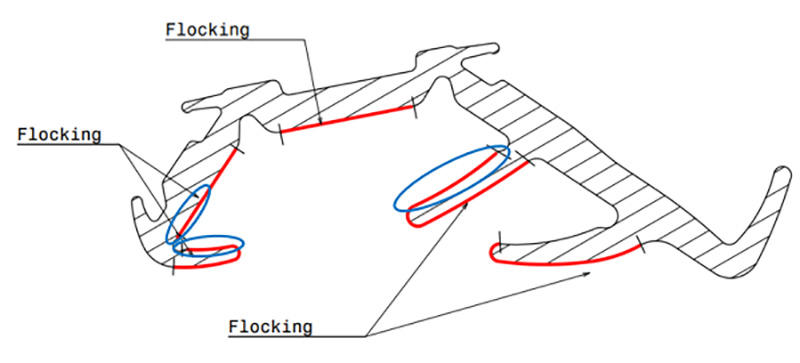

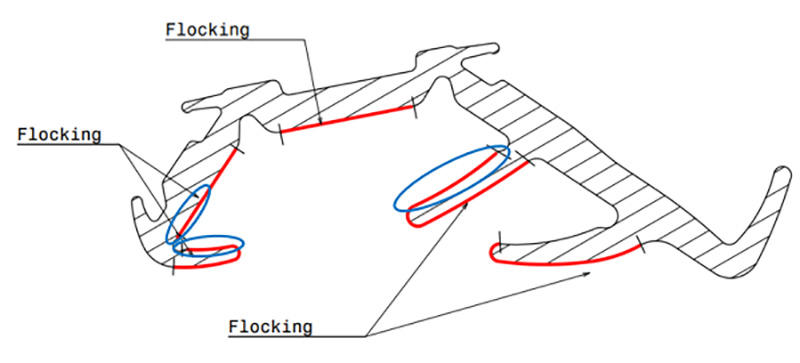

Flocking surface, according customer’s drawing, red areas need flocking, but some which marked by blue are impossible to flocking, so we suggested customer cancel flocking for these areas.

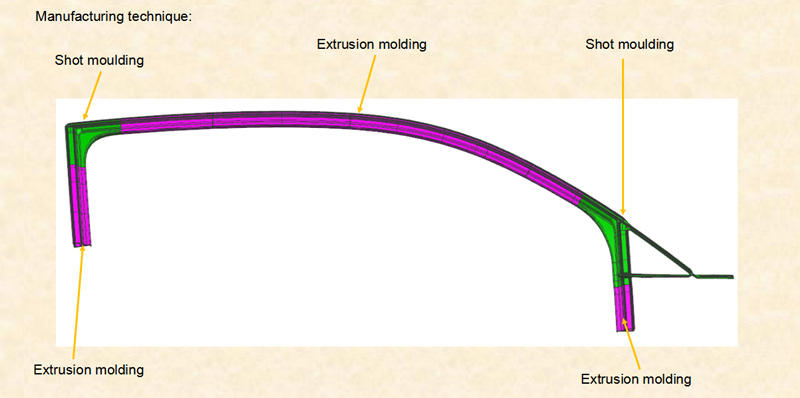

Shot moulding and extrusion, As show you, green areas shot moulding, extrusion molding on the purple area.

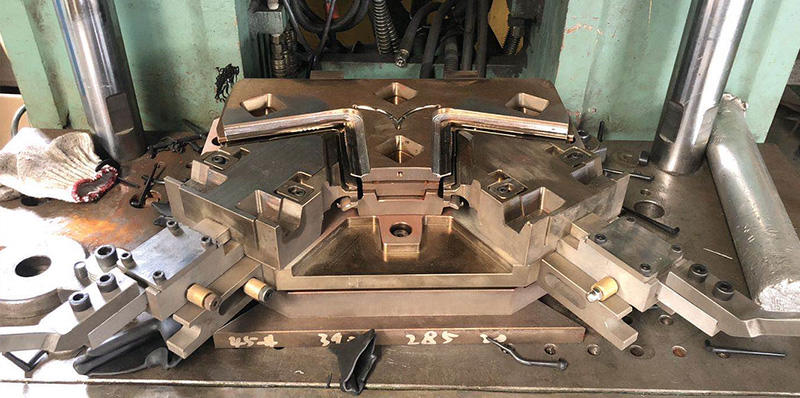

Complex extrusion, extrusion made by extrusion mold(picture on the right), extrudion molding need unfold, during trial, need adjust a few until match customer’s drawing.

Finished tooling, shot molding made by shot mold, It fuse the shot molding with extrusion molding.

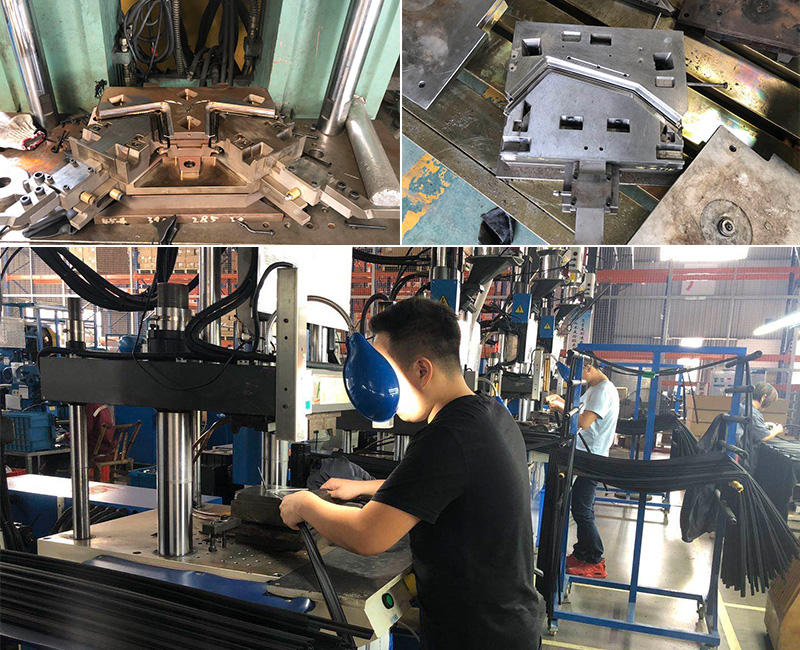

3: The workshop where we work

When the product is extruded, some products need to be processed twice according to the shape of the product.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.