Why choose Oemmold over other plastic molding companies?

The manufacturing team at Oemmold has decades of experience in plastic part design, tooling, and defect-free manufacturing methods. If you’re newly in need of a plastic molding company or tired of all the hoopla that your current plastic molding suppliers are giving you, please contact us for a quote or manufacturing consultation today. Below are some great reasons to choose Oemmold as your plastic molding supplier.

Custom part design consultations

Part design for injection molding can be made simple with the right knowledge or advice. At Oem we offer free part design consultations to help our customers avoid the costly burden of needing to re-design or re-prototype parts later in the product launch cycle. Not all plastic molding suppliers offer this service, but we are happy to do that. Some of the main topics for injection molded part design reviews are:

1. Maintaining consistent wall thicknesses throughout the part design

2. Using nominal wall thicknesses that make sense for the proper function of the part

3. Applying the proper tooling draft angles to part surfaces and parting line shut-offs

3. Avoiding sharp corners on part features that can become rounded

4. Choosing the proper target plastic material for the part

5. Advanced target cost planning

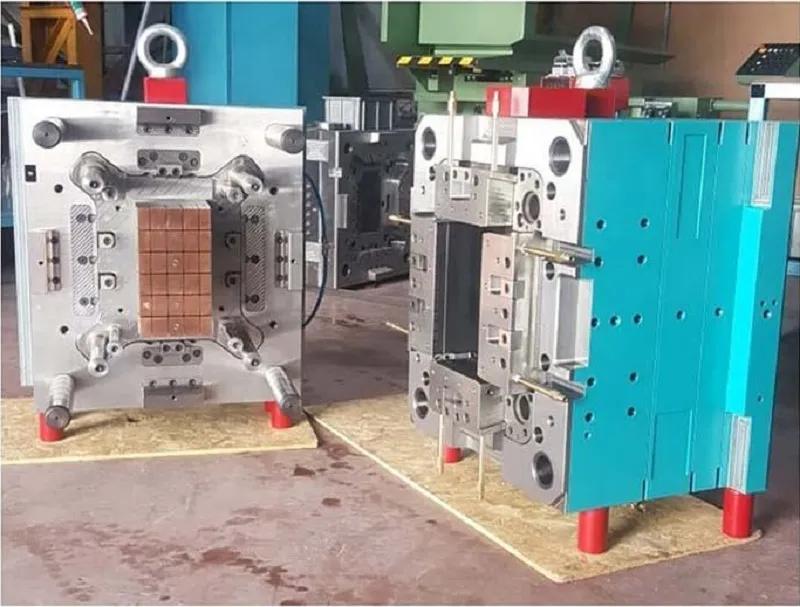

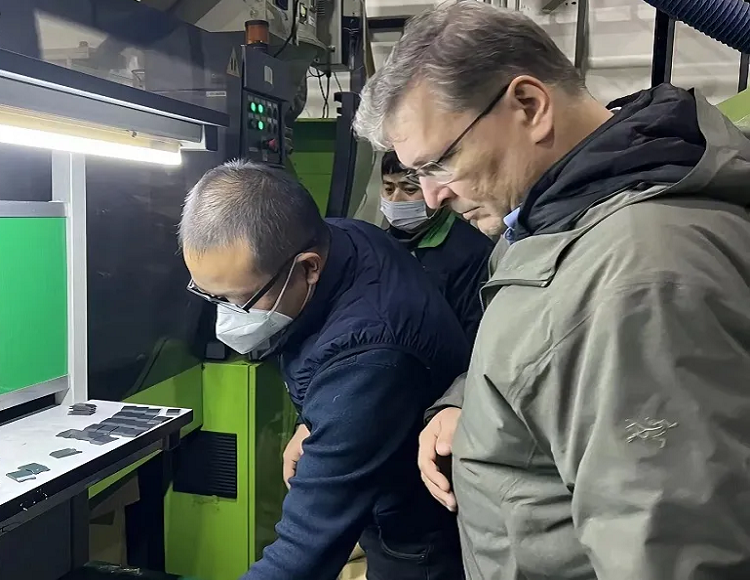

We make your plastic injection molds in house

Many plastic molding suppliers do not have in-house capabilities for building customer molds. If your project will require custom molded parts it’s important for you to understand the risks to your project’s success when working with injection molding companies that outsource customer mold builds. Without in -house mold making capabilities, your plastic molding supplier will not have total control of your project timeline or initial part quality. In fact, if your plastic parts supplier is outsourcing your injection mold, there is a very good chance it is being a foreign trade company. At oemmold we build all of our customer’s injection molds in our factory. We have total control of the mold design, the mold build timeline, and the quality of your injection mold. Your injection mold requires a large up front investment and will become one of your significant business assets, so it is important for you to have the opportunity to know who is making it before you send tooling deposit money to your plastic molding company.

We keep customers happy

Our approach to being a successful plastic molding supplier is simplistic madness. We make customers happy they do business with us. With a focus on good communication, fast lead times, affordable prices, and no surprises, Oemmold customers never need to look anywhere else for their custom-molded parts. In manufacturing, high customer satisfaction is the result of a well-run business that focuses on:

- High-quality defect-free production

- On-time order delivery

- A never-ending pursuit to get better